Lakeland Industries is one of the world’s leading and largest manufacturers of personal protective clothing and owns factories worldwide. Lakeland is a highly respected brand in the chemical, pharmaceutical, mining, environmental remediation and damage control, recycling, fire, composites, offshore and many more industries.

Lakeland Industries develops and manufactures a very wide range of innovative protective clothing in its own factories.

What makes Lakeland products special?

Lakeland has a strong focus on user protection and well-being when developing their innovative protective suits.

Lakeland has managed to differentiate itself from its competitors by developing high-tech products and designs that provide the user with extra safety and extreme comfort.

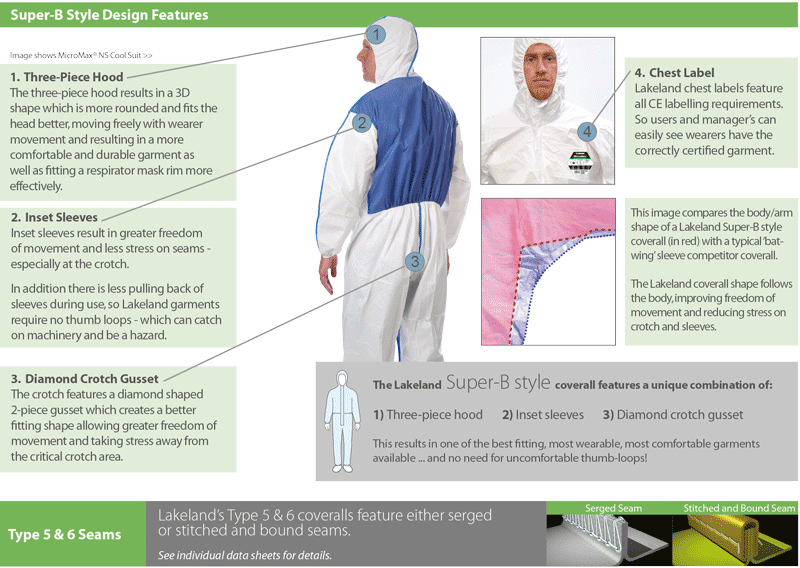

Best-in-class wearing comfort – Super-B Style

Lakeland is recognized for their Super-B Style design which includes the following features/benefits:

Personal protection in the claims service industry

Employees in the claims service industry can be exposed to a wide range of substances and chemicals in their daily work that require effective protection. In the property damage restoration industry, it should also be a top priority to make sure that the employee is properly protected for the work that needs to be done, such as mold remediation, asbestos abatement, PCB remediation, fire damage restoration, body recovery, demolition, etc.

Due to the many environmentally and health hazardous particles and chemicals that sanitation workers handle and are exposed to, as well as working in hard-to-reach work areas such as crawl spaces, attics and the like, it would be virtually impossible to choose just one type of protective suit to cover the many different tasks. 100% protection against substances, particles and chemicals is essential, but wearing comfort is also important for wellbeing and work efficiency.

For example, a tight and closed type 3 and 4 chemical suit would be the wrong choice for asbestos remediation or any other type of remediation where protection against particles is required. Here, an approved type 5 suit with greater comfort compared to, for example, a type 2 suit would be more suitable. breathability should be the preferred choice. On the other hand, chemical work should be carried out with a type 3 and 4 suit or alternatively a type 6 suit, but only light spraying with disinfectants, cleaning fluids, etc. and where the suit is not exposed to wear and tear, such as working in crawl spaces and other areas that can damage the suit. Here, a hard-wearing and decidedly chemical-resistant type 3 and 4 suit should always be chosen.

Showing all 3 results

Contact outside opening hours

Tel. +45 4021 4787

Monday - Thursday: 8.00 - 16.00 Friday: 8.00 - 14.30

T: +45 7442 6292

info-nac-europe.com

NAC Europe is geared to serve all of Europe.