Non-destructive drying out of wall, floor and ceiling structures with infrared technology after water and moisture damage.

BET on the original!

First with infrared

For more than 15 years, WMT’s dedicated engineers have been developing and constantly optimizing the company’s well-known products based on infrared heating technology.

Drypanels – heating panels from Austrian WMT Thermosysteme GmbH are therefore today a highly valued and value-adding product in the European damage service industry.

WMT Drypanels have been successfully used in Scandinavia for more than 10 years now and have contributed to the quick, simple, cost-effective and highly efficient drying of thousands of problematic moisture damages.

Drypanels work perfectly on their own or as a system component in a larger drying/dehumidification system based on adsorption or condensation dehumidification.

Drypanel

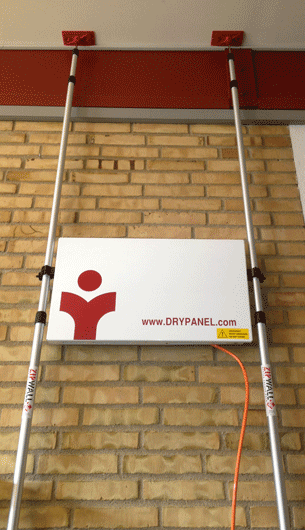

Infrared DryPanel® from WMT successfully accelerates the remediation of water damage and the reduction of moisture in walls, etc. Moisture is removed by evenly heating the building structure using infrared radiant heat and is effectively released into the room air through evaporation.

Areas of application

Due to their low weight and flexible installation options, infrared DryPanel® are not only ideally suited for the remediation of small and medium-sized water damage, but also contribute as a system component for larger and more complex water damage along with sorption or condensation dehumidification.

Innovative technology for the highest demands

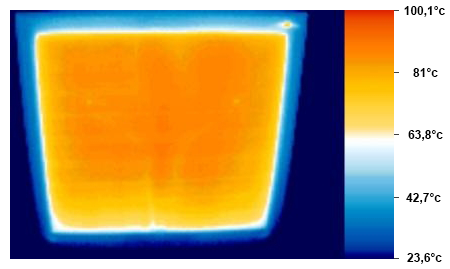

Infrared DryPanel® set new standards in terms of reliability and energy efficiency. Over 50,000 hours of endurance testing guarantees high on-site reliability with little installation effort and no maintenance costs. The innovative Flatpanel technology impresses with its short heat-up times and low power consumption, as the entire room does not need to be heated. Due to the low power connection value, it is easily possible to place multiple devices in a room.

Infrared principle

Infrared heat is based on the principle of solar radiation. While conventional heating methods only heat the air, buildings can absorb radiant heat directly. DryPanel® uses this principle for a fast and targeted drying effect. The high performance of our infrared heating panels is not only reflected in the power consumption, but also in the excellent ratio between energy used and radiant heat delivered.

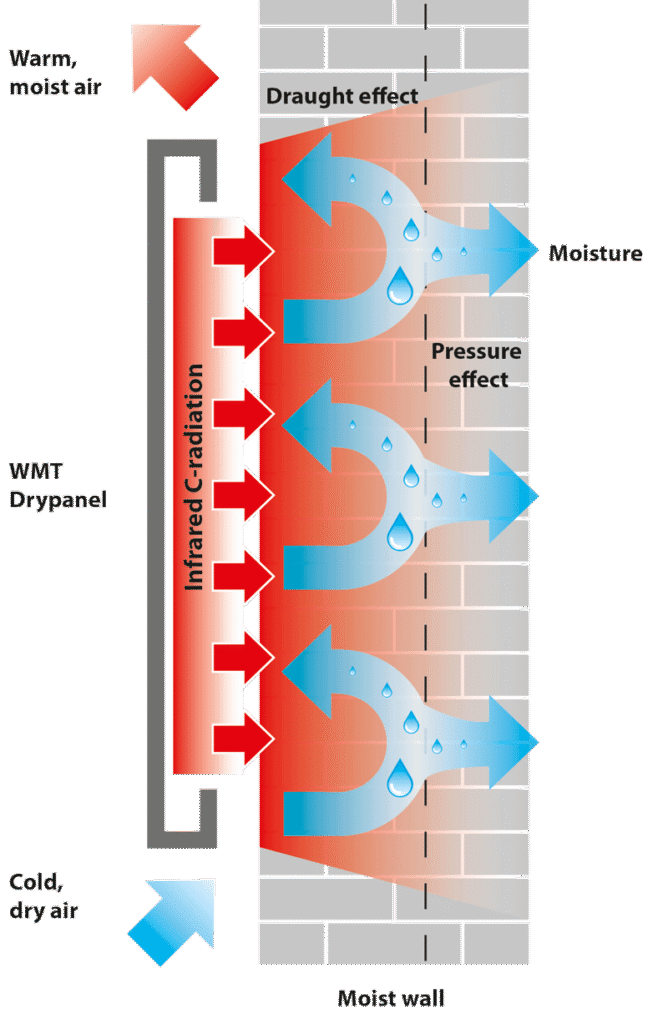

Drying process – Principle of operation

Using WMT FlatPanel technology, infrared C radiation is generated on the inner heating plate, heating the surface of the wall and the air space between the plate and the brickwork first.

The stored hot air absorbs moisture and rises up through the vent slot, while cool and dry air is drawn in from below. This circulation means that the space between the panel and the wall is never saturated with moisture and the masonry continuously dries out.

At greater wall thicknesses, there is a double effect. In addition to the described suction/chimney effect, there is a pressure effect due to the laws of building physics. These are based on the fact that moisture always moves away from hot zones. This also releases the moisture on the opposite wall surface into the room air.

The resulting infrared radiation heats through even masonry of 50 cm and above, depending on the ambient conditions.

With this unique drying process, WMT Infrared DryPanels efficiently and gently accelerate water damage restoration with low power consumption.

The illustration on the right shows how infrared heat rays penetrate deep into building structures and dry efficiently and reliably.

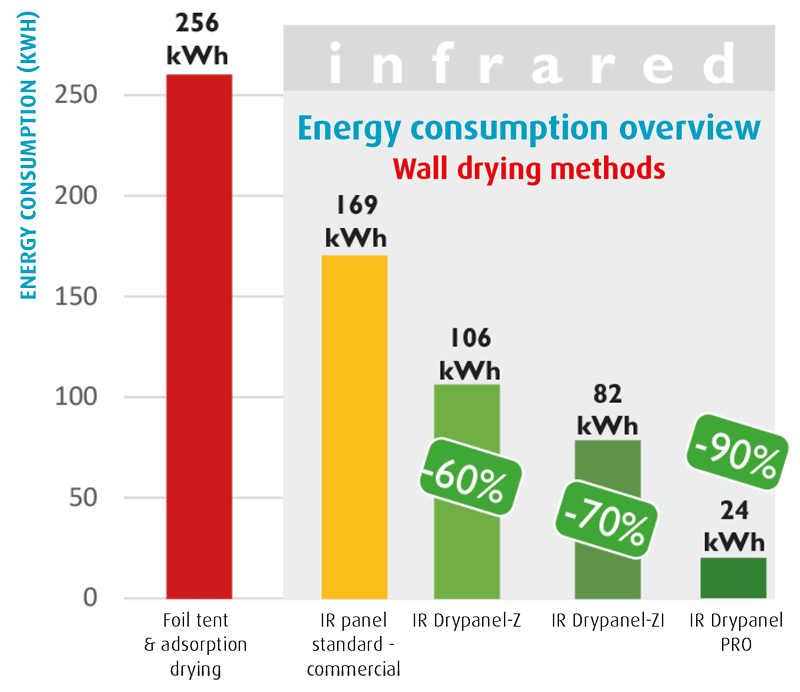

DryPanel is the champion of energy saving

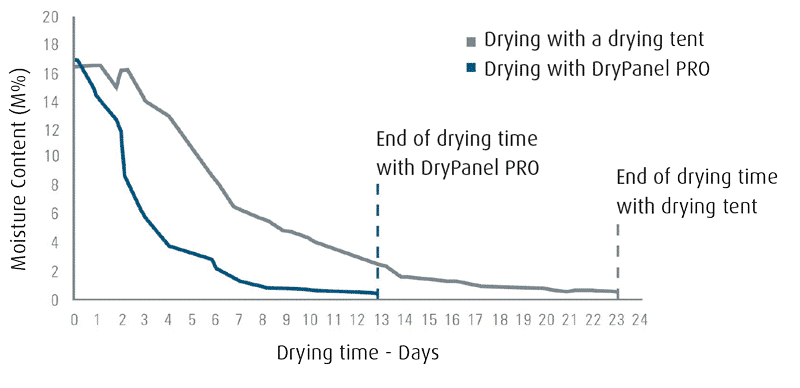

All WMT Drypanels are great energy savers, but the new Drypanel PRO goes above and beyond!

When comparing the energy consumption of different wall drying methods, Drypanel PRO clearly emerges as the most efficient solution.

Contact outside opening hours

Tel. +45 4021 4787

Monday - Thursday: 8.00 - 16.00 Friday: 8.00 - 14.30

T: +45 7442 6292

info-nac-europe.com

NAC Europe is geared to serve all of Europe.