Description

Infrared principle

Infrared heat is based on the principle of solar radiation. While conventional heating methods only heat the air, buildings can absorb radiant heat directly. DryPanel® uses this principle for a fast and targeted drying effect. The high performance of our infrared heating panels is not only reflected in the power consumption, but also in the excellent ratio between energy used and radiant heat delivered.

Ideal ratio between energy consumption and moisture removal

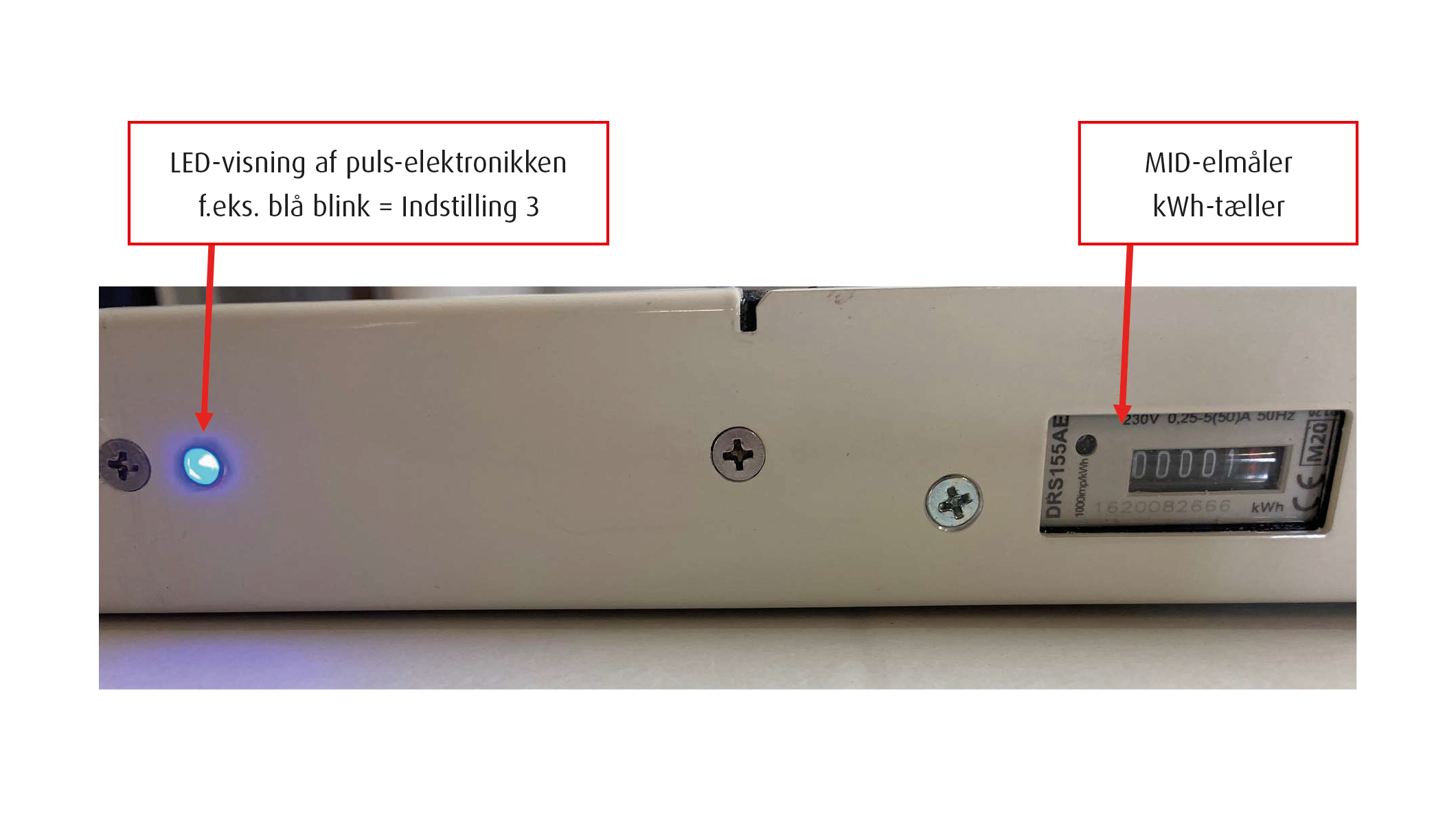

WMT’s drypanel® infrared heating panel radiates around 85 degrees and heats the wall to around 60 degrees. However, due to the special construction, the back of the panel only has a minimally heated surface temperature. This targeted radiation makes drypanel® extremely effective.

Infrared heating panels from WMT effectively speed up water damage restoration and reduce moisture in the wall. Thanks to even heating of the construction with infrared radiant heat, the moisture is drawn out and released through evaporation into the air in the room.

- Drying out walls after water damage

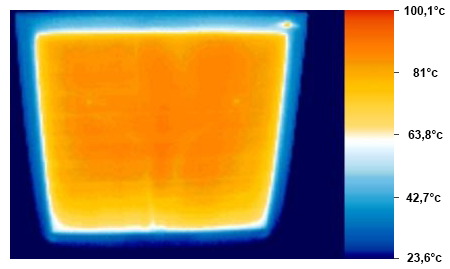

Using infrared heat from WMT DryPanels not only simplifies the restoration of localized water damage, but also provides a comfortable solution for affected customers. DryPanel® is installed using a plinth or wall mount directly into the affected wall area. Using infrared C-rays, the masonry is heated and the moisture on the diffusion-open side is silently released into the room air. In closed rooms, regular ventilation or a condensation dehumidifier prevents the air from becoming saturated with moisture.

Partition walls

If a partition wall is not diffusion-tight on both sides, place Infrared DryPanel® on the diffusion-tight side of the wall. At the building physics pressure effect described on page 4 of the brochure, the moisture is then released to the opposite (diffusion-open) side of the wall. For masonry that is permeable on both sides (25 cm perforated bricks), the average drying time is 8-10 days.

Exterior walls

When drying out exterior walls, it should be noted that if the exterior is made diffusion-tight and must not be damaged, an interval drying method should be used in any case to prevent moisture from penetrating further into the masonry.

- Drying door and windowopenings

The DryPanel BT300 and DryPanel BT200 models are ideal for use in narrow niches and window and door openings. This way, potential issues with a large dehumidification project can be addressed from day one, helping to shorten the overall dehumidification time for that project.

- Water damage in insulated concrete floors – drying out in the plinth area

When the insulation layer is dried using the compressed air process, the compressed air blown in between the concrete floor and masonry escapes. The moisture contained in the released air is absorbed in the plinth area by the masonry. Here, the BT300 offers a simple solution for plinth mounting. Thanks to the low connection power, you can easily connect up to 15 units. BT-300 to a 16A circuit and place them around the room in the socket area. By heating the masonry locally, moisture penetration into the plinth area is prevented and the overall drying time is greatly reduced. See illustrations in the brochure.